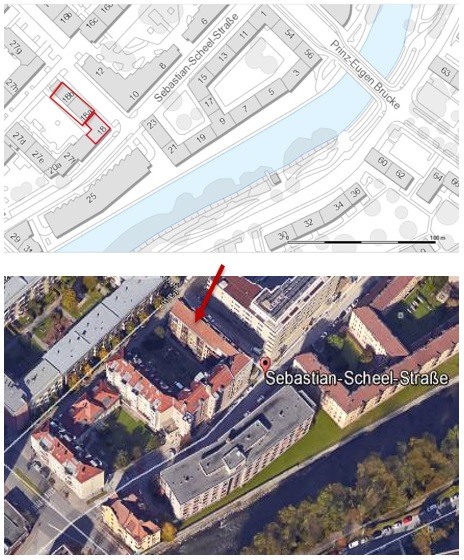

Sebastian-Scheel Straße 18-18b

Name and address

BEST 3 | “Sillblock” - Sebastian-Scheel Straße 18-18b

Map

Source: http://city-map.innsbruck.gv.at

Description

A social housing complex, built in 1940, has been refurbished whilst people were still living in the building. Single-stove ovens were exchanged against electric panels but gas heating was maintained where existing from before. A PV-plant on the roof was installed to enable some amount of energy self-supply. Decentralized ventilation systems were implemented in 1/3 of the flats. In addition, several additional improvements to the building have been incorporated in the refurbishment process, such as new balconies and elevators.

Ownership

Innsbrucker Immobilien IIG

Gross volume: 7.653 m³

Gross surface: 2115 m²

Number of dwellings: 34

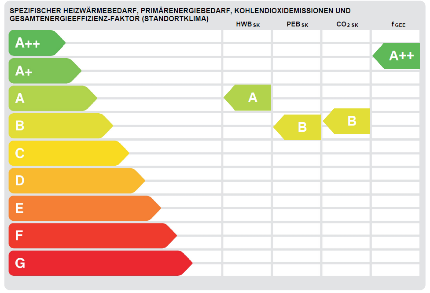

Energy performance

BEFORE

Heating demand (EPC): 193.3 kWh/m*a

Heating demand (PHPP): 151 kWh/m*a

TARGET/AFTER

Heating demand (EPC): 19.7 kWh/m*a

Heating demand (PHPP): 18 kWh/m*a

Main lessons learnt

The comprehensive refurbishment of a building is a combination of energy solutions and improvements for user comfort. Investments have to balance these two aspects in an optimal way. As such, challenges are of financial, technical and social character.

In respect to tenants, the burden of noise, dust and intrusion into personal space, as well as disturbance of daily routines, is enormous. Permanent dialogue and crisis management demand special abilities of a building manager.

Finding optimal and cheap solutions with less interference into the building structure is especially important concerning ventilation and heating systems. It requires a repeated revision in the planning process. Here, a centralized heating system was given up in favor of exchanging single ovens with single electricity heating devices, fed by house owned PV. Also only 1/3 of the apartments have been equipped with ventilation systems – only those which were empty and those where the arrangement of tubes could be implemented without major interference with the building structure (all the flats on the top floor, where tubes are now led through the attic).

After refurbishment, it takes a long while until frustration of the tenants about the building process is substituted by happiness about their newly insulated building and reduced heating demand. Proper usage of a passive house requires intensive communication with the tenants who are advised to change their lifestyle in order to reach optimal energy savings (no long-term tilting of windows, or T-shirts in winter with heating above 25 ͦC). Also, reaching optimal usage (self-supply) of the PV-electricity during daytime takes time since electrical devices have to adapt to usage habits.

Building envelope

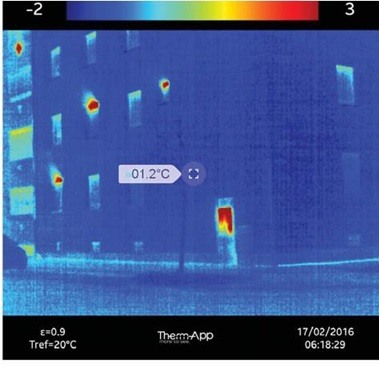

Sillblock is a typical building block constructed in the second half of the 20th century with related challenges in regard to insulation, thermal bridges of loggias, electric cables, low performing windows, poor roofs and dug out cellars, etc.

Technical system

Decentralized heating system with gas, electricity, oil, wood – several single ovens

Thermal imaging before refurbishment

Energy performance certificate

Category E

Concept

A full refurbishment was planned of the building envelope, the heating system and air ventilation As accompanying measures, disability access through elevators and new balconies (thermally decoupled) should be implemented.

Energy solutions

- Replacement of old heating systems by a centralized heating system was planned (but finally not implemented);

- Removal of all single ovens.

- Integration of solar electricity

- Installation of a centralized ventilation system

Performances targets

Reduction of total energy consumption by more than 60%.

Envelope details

Roof to wall insertion section (thermal bridge)

Triple-glazing windows with building integrated PV 5Wh shading element.

Insulation of the attic floor with a 40 cm-thick layer of cellulosic

Ground to wall section (thermal bridge)

Additional wood-wool thermal insulation of the lowest storey ceiling (17.5cm).

Wall to fenestration section (thermal bridge)

Thermal insulation of façade (22cm EPS) and thermal insulation of inner yard (12cm PU). Perimeter Insulation in a range of 6 -14 cm

Technical system

Mechanical ventilation

Centralised ventilation systems were installed. However only 1/3 of the apartments are equipped with ventilation systems: only those which were empty and those where the arrangement of tubes could be implemented without major interference with the building structure (so all the flats on the top floor, where tubes are now led through the attic).

Electric renewable integration

Installation of a PV system on the roof. Characteristics are as bellow:

Nominal power:17,34 kWp

PV array area: 113,1 m² Module type: Solarwatt

Inverter Type: AE Conversion

Mounting type: Roof mounted parallel Elevation: 574 m a.s.l.

Tilt: 38°

Azimuth angle: 225 °/135°

Model: Power reduction for consumers

Stakeholders involved

Contracting authority

IIG - Innsbrucker Immobilien GmbH & Co KG

Project manager

DI Walter Aistleitner

Architect

din-a4 Architekten

Envelope designer

Technical system designer

HSL planning – Alpsolar Klimadesign electric planning – Zösmayr Elektrotechnik

Windows supplier

Internorm

Costs and financing

Refurbishment costs

Not applicable

Financial resources

Most of the works are financed by IIG, using rental reserves accumulated from previous years. The monthly rent is on average 3.56 €/ m² / month and are not to be increased for this project. The operational costs are (without heating and electricity) about 1.58€/m²*month.

In addition to IIG’s investment, the refurbishment is co-financed by the European Union.

Payback period: 10 years (using an interest rate of 3 months Euribor + 0,43 %).

Implementation planning

1 - Signature consortium agreement: 2014

2 - Start of refurbishments: 05-2015

3 - Completed refurbishments: 11-2016

Work progress

Important points of refurbishment process and short description

You may find here three pictures of the construction process showing some steps of the external and internal refurbishment process. It shows activities of the façade insulation, of preparation and implementation of the ventilation system.

Architectonic concept

Detail of balcony/elevator solution

Thermal image after insulation

Envelope characteristics

- Facade insulation: 22cm Expanded Polystyrene (EPS), U-value 0.15;

- Roof cellulose 40cm, U-value 0.1 -0.12;

- Ceiling basement U-value 0.26; glazing Ug 0.5 and Uw 0.66;

- Shading built into the window;

- Flanking insulation: 12 cm for reduction of thermal bridges;

- Balconies thermally uncoupled. The construction of the balconies is performed in cross laminated timber (CLT) for floor and ceiling, and steel columns.

- The existing roof has been checked statically for photovoltaics and for solar thermal energy.

Technical system

Electric installation works and installation of ventilation systems have been properly done. Elevators have been fully completed. Six empty dwellings have been retrofitted completely and have been re-settled after refurbishments. Additionally, some tenants have agreed on monitoring of the energy use, and of the electricity consumption, as well as of the air quality.

Due to tenant’s refusal to implement a central heating system, only single stove ovens were exchanged with electric heat panels. All flats heated with gas were kept as they are.

Renewable energy sources

The PV installation has a capacity of around 17,34 kWp. This electricity can be used for personal consumption (off-grid system) or can be fed into the public electricity network (grid-connected system). There are power inverters with 0,5 kW for each flat, linked to two PV modules each. So far, for a test-period between June and November 2017, own domestic consumption rate resulted in around 56%. Excess electricity is fed into the grid. This domestic renewable energy consumption could be improved if electrical devices (especially hot water boilers, washing machines etc.) were fed by the PV mainly during daytime (sunshine hours).

Energy performance after refurbishment

Calculated energy consumption per m2 of total used conditioned floor area of about 40 kWh/m²*a. (EPC) was reached, and electricity savings of 30% are foreseen.

Energy performance certificate (EPC)

Building owner

Innsbrucker Immobilien IIG

Architecture / Engineering

din-a4 Architekten

Contact

Standortagentur Tirol

Tel : +43.512.576262