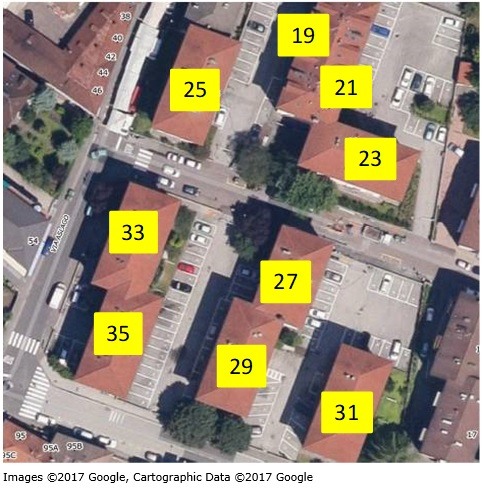

Housing complex - Via Aslago

Name and address

Aslago-Oltrisarco Quarter

Via Aslago 25-27-29-31-33-35

Map

Images ©2017 Google, Cartograghic Data ©2017 Google

Description

Aslago Area is located in the east side of the city of Bolzano, close to the mountain called Colle di Bolzano/Kohlern and to the historical unit in Via Claudia Augusta. The buildings were built in the 50’s.

Ownership

Municipality of Bolzano

Gross volume: circa 18.330 m³

Gross surface: 5.524 m²

Number of dwellings: 70

Energy consumption excluded RES contribution

BEFORE

263,1 kWh/m² year (heating)

AFTER

26,0 kWh/m² year (heating)

Energy consumption included RES contribution (Total Building Energy Use)

AFTER

33,19 kWp of photovoltaic plan

440kW Biomass boiler

Detailed characteristics of building

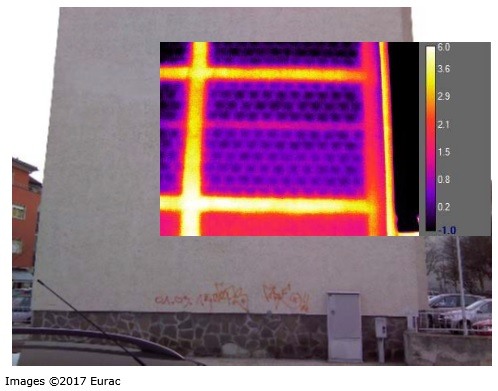

The group of buildings in Via Aslago Street dating back to the 1950s was built at a time when no attention was paid to energy aspects. Moreover, the buildings had never been subject to renovation and/or extraordinary maintenance. From an energy point of view they were also positioned in class G of CasaClima certification. For the buildings in Via Aslago there were big problems regarding energy efficiency, and in this case thermal bridges, airtightness of the windows and doors, presence of mould and interstitial humidity inside the housing and heat dispersion of the external walls and roof. In addition to the above conditions, the buildings had no lift and no terraces.

Plot map

Building envelope

The structure has a reinforced concrete frame and inter-storey slabs with a brick-concrete type structure.

Technical features:

U= 1,36, façade / wall

U = 1,33 W/m2K, insulated brick roof

U = 1,33 W/m2K, basement ceiling to cellars with predalles type structure

Windows:

Double glazing: Ug = 3,3 W/m²K

Technical system

The existing hydronic system is centralized and the energy for heating and DHW is provided by two thermal power stations:

- One power station for the numbers 27, 29, 31, 33, 35;

- Another one for the numbers 19, 21, 23, 25.

Gas fired thermal power plants have been built in 1983 and boilers were installed to that date, as part of the circulation pumps. These have been progressively replaced with more efficient models during extraordinary maintenance works.

The water is distributed through columns rising from below. Every room has its own radiators.

Thermal image before refurbishment

Other relevant technical aspects

Some buildings, specifically building under number 27, have static issues and needs measurements to check the availability of additional storey.

Concept

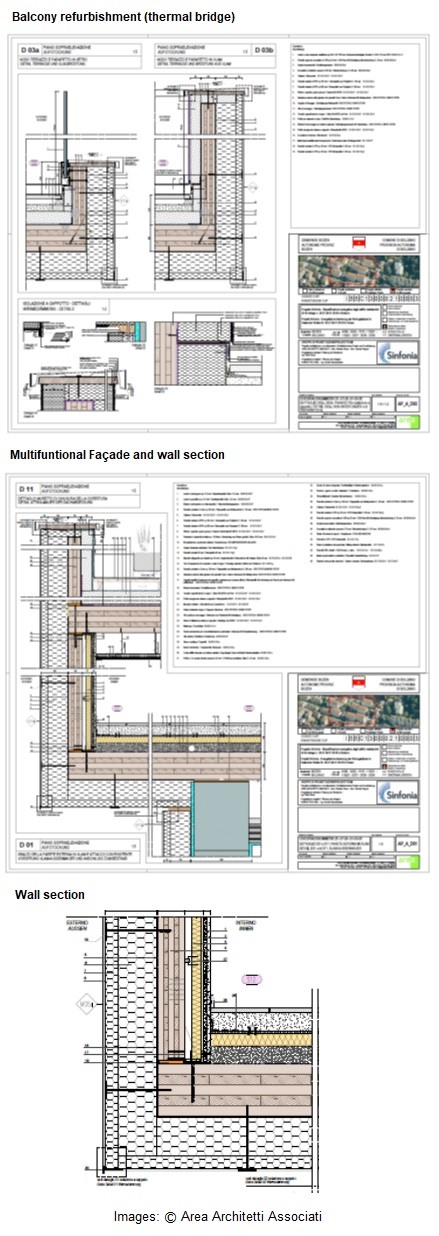

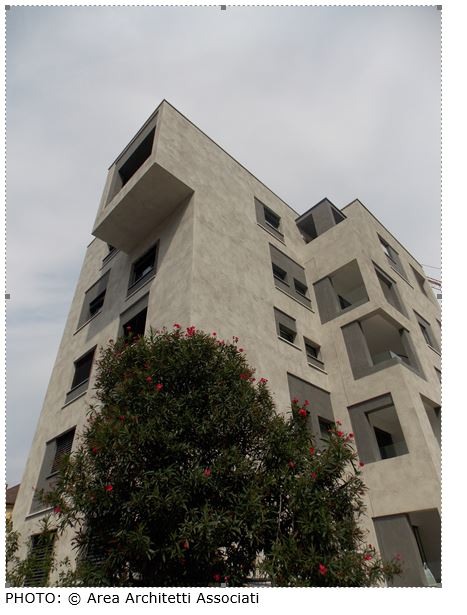

The architectural aspect of existing bodies did not have documentary features or historical value that necessarily justified its maintenance. The new "skin” is characterized by a design with homogeneous aesthetic qualities, which, without distinction, covers existing and added bodies. This allows, by adding and subtracting (projections and reentrances) to the last added plane, a radical change of the overall volumetric perception, at the same time more homogeneous and more dynamic.

The volumetric articulation along with the effects of the façade diversification obtained with rectangular breaks results in a remarkable improvement in overall aesthetics.

In the façade, the shadow and diversification effects are obtained through slight increases in thickness of the insulating material as well as chromatic differences and granulometry differences in the plaster.

Addition of the elevator involves the introduction of landing plans to all stairwell mezzanines. This has been solved with an externally reinforced and statically autonomous concrete structure, duly anchored to the building.

By extending the elevator structure on both sides without interfering with the existing one, it has been possible to make balconies (or loggias) for two of the three accommodations of each existing plane.

As for the elevation, a total of 14 new housing units, 3 housing units (29-31-33-35) and two housing units in civic 25 have been designed. Civic 27 was not raised due to static reasons. The elevation involved the demolition of the existing roof in concrete and bricks, the cut of the perimeter curb in concrete and the insertion of an X-lam wood separating structure for both walls and new floors. The exterior walls got a thermal insulation like existing masonry. The top of the building was covered with a flat roof with extensive green roofing.

Energy Solutions

The horizontal roof was insulated through XPS panels (20cm thick), the external walls were insulated with EPS panels (15 – 20 cm thick)

The floor toward the cellar was insulated with rock wool panels (10 cm thick)

New windows wood /alu with triple glass, improved airtightness with Blower door test 1,50 vol/h n 50

External walls: U = 0,13 W/m2K

Ceiling to cellar/garage: U = 0,3 W/m2K

Roof: U = 0,13 W/m2K

Windows:

Triple glas Ug = 0,5 W/m2K

Alumininium wood frame: Uf = 0,97 W/m2K

Heating and domestic water generation subsystem: decommissioning of existing gas boilers and installation of a centralized system fed by two pellets boilers

Emission subsystem: maintenance of radiators in existing apartments

Integration in all apartments of a decentralized / not canalized system for controlled mechanical ventilation

Renewable sources:

Installation of a 33.0 kW photovoltaic system on the roof

Financing Model

Sinfonia covered the part of costs which allowed to bring the energy performance level above the legal requirements, the rest of the renovation costs were covered with the national contribution called conto termico and the funds of the Autonomous Province of Bolzano (L.P. 13/98).

Envelope details

Technical system

Mechanical ventilation

Decentralized / not canalized system for controlled mechanical ventilation

Heating system and Hot water distribution

Heating and domestic water generation subsystem: decommissioning of existing gas boilers and installation of a centralized system fed by two pellets boilers.

Emission subsystem: maintenance of radiators in existing apartments

Stakeholders involved

Architectural project: AREA ARCHITETTI ASSOCIATI Roberto Pauro – Andrea Fregoni

Plant engineering project: Ing. Norbert Klammsteiner – Energytech (BZ)

Responsible for the Procedure (RUP): Geom. Diego Andreotta

Project Co-ordinator: Dott. Emanuele Sascor

Construction company: Raggruppamento Temporaneo di Imprese made up by the firms Nerobutto Tiziano e Francesco S.n.c , Ediltione S.p.a. , Termoidraulica Parotto Vittorino S.r.l. , A.P. Elettrica di Alberto Pecoraro & C. S.n.c. Metallbau Glurns S.r.l.

Energy consultant, scientific support: Agenzia Casa Clima, Eurac

Costs and financing

Refurbishment costs

- Renovation works: € 5,338,330.15

- Monitoring: € 167,463.16

- Monitoring system: € 6,897.95

- Feasibility study: € 9,410.00

- DL (Works’ supervision): € 26.906.58€

Financial resources

Renovation works:

- Sinfonia (50%): € 867,540.00€

- Conto termico (65%): € 3,067,906.75

- AutonomousProvinceofBolzano(for architectural barrier-free design implementation, 30%) € 486,000

Monitoring:

- Sinfonia € 247,000.00

- DL (Works’ supervision): € 72,800.00

- Monitoring system: € 7,795.00

- Feasibility study: € 9,410.00

Implementation planning

1 - Signature consortium agreement: 2014

Approval of the European Community; the City Council of Bolzano approved the participation at the project, start of the Sinfonia project.

2 – Planning of the energy pilot district: 2014

3 - Tender procedure for the energy refurbishment project: December 2015

A design competition was chosen.

4 - Approval of the preliminary, the final and the detail project: July-December 2016

5 - Tender procedure for the energy refurbishment works: September 2017

6 – Start of the energy refurbishment: October 2017

7 – End of the energy refurbishment: July 2019

8 – 60 days for the refinement works: July 2019-September 2019

9 – Administrative and technical validation: July 2019-January 2020

Work progress

Installation of the newly added floor

Building envelope façade

PV panel system

VMC decentralized mechanical ventilation system

Architectonic concept

Envelope characteristics

The horizontal roof was insulated through XPS panels (20cm thick), the external walls were insulated with EPS panels (15 – 20 cm thick);

The floor toward the cellar was insulated with rock wool panels (10 cm thick);

New windows wood /alu with triple glass, improved airtightness with Blower door test 1,50 vol/h n 50.

External walls: U = 0,13 W/m2K

Ceiling to cellar/garage: U = 0,3 W/m2K

Roof: U = 0,13 W/m2K

Windows:

Triple glas Ug = 0,5 W/m2K

Alumininium wood frame: Uf = 0,97 W/m2K

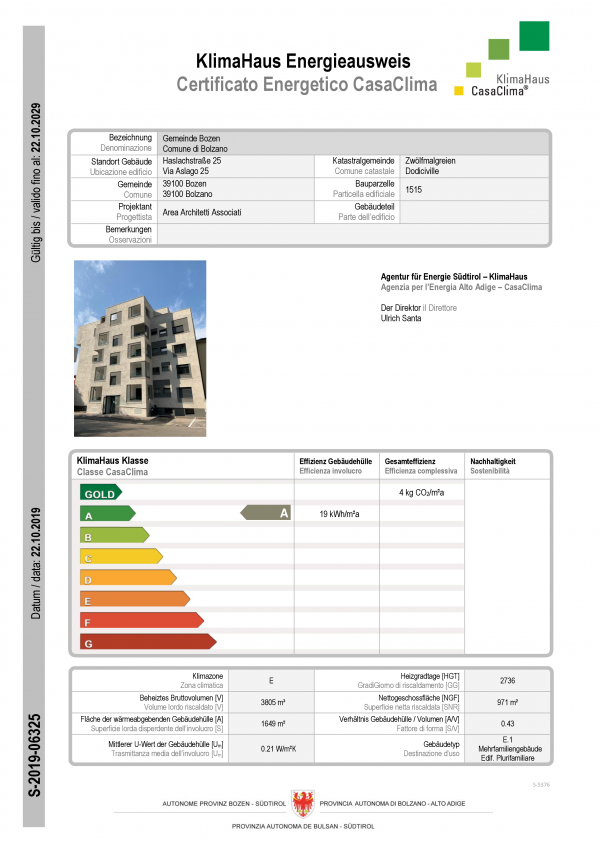

Energy efficiency certificate

Monitoring system

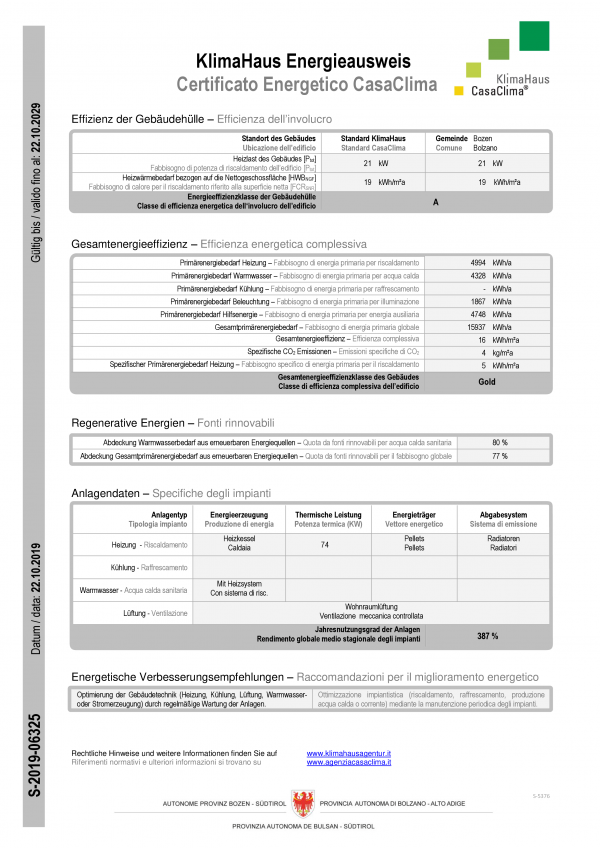

Sometimes refurbishment works alone are not enough to reach high goals in terms of energy savings. Monitoring systems can help boost the effectiveness of retrofit interventions by assessing the performance of specific technologies while encouraging tenants to reduce their energy consumption. The monitoring system installed in the housing complex of via Aslago collects data produced by existing appliances, measures conditions from internal areas, and at the same time, stores such data for further assessment and future improvements.

The monitoring system is made up of different sensors that collect data from different signal inputs. All sensors are connected to the same network, making it possible to collect data through a data logger; which can also store data on a temporary basis. The data logger transfers the collected data to Eurac Research servers via an Application Programming Interface (API) to be validated and stored in a time-series database. Once data are transferred, they are erased from the data logger.

The interface that stores data in Eurac Research servers allows researchers to retrieve data and perform calculations that are used to provide other services. Specifically, a web application was developed to provide feedback to tenants. It allows to visualize energy consumption and environmental conditions on a real-time basis and sends messages to raise the awareness of tenants of possible consumption misbehaviors, suggesting how to solve them. Such application is displayed on a mobile device as an in-home display. The interface also allows to retrieve collected data in order to assess the performance of specific technologies.

Architecture from Monitoring and Feedback systems

Feedback to tenants

Monitored measures

The monitoring system collects data every 5 minutes and stores the following measures:

(A) Measures from buildings

- Energy consumption

- Photovoltaics

- Solar thermal

- Elevators

- Central heating

- External lightning

- External temperature (where available)

(B) Measures from apartments

- Energy consumption

- Electricity

- Domestic hot water and Heating

- Ventilation system (where available)

- Environmental conditions

- Temperature

- Relative humidity

- Carbon dioxide concentration

- Windows status (open or close)

- Water consumptions (hot and cold)

(C) Measures from appliances in some apartments

- Energy consumption

- Fridge

- Washing machine

- Oven

- Hob

- Dishwasher

Building owner

Municipality of Bolzano

Architecture / Engineering

Area Architetti Associati

Contact

European Academy of Bozen/Bolzano (EURAC)