IKB Smart District

Name and address

IKB Smart District

Langer Weg 32

6020 Innsbruck

Map

Source: Google Maps

Type of installation

The IKB-Smart-District includes several buildings. In the center is the Showroom were most of the units are located. On nearly all roofs PV plants are installed. Between the location “heating room” and the Showroom the heat pipes were built, and a micro heating grid installed. The heat storage tanks are located in the Showroom and the heating room. The other departments like the Recycling Center and the electricity grid department are connected by a micro gird for electricity. Charging stations for the electrical cars are also located close by the showroom.

Ownership

Innsbrucker Kommunalbetriebe AG

Capacity

Biogas CHP

262 kWel / 375 kWth

Heat Pumps

2 x 95.7 kWth

Heat storage Tanks

1 x 10,000 litre

6 x 1,500 litre

Electric heating element

200 kWel

Heat exchanger sewage water

150 kWth

PV-plant – LW32

14.82 kWp

PV-plant – RCH

122.58 kWp

PV-plant – Triendlgasse

50.76 kWp

Battery storage

27.60 kWh

Detailed characteristics of the device / infrastructure / service

The project “IKB Smart District” includes the following major components:

- Biogas CHP

- Heat Pumps

- Heat storage Tanks

- Electric heating element

- Heat exchanger sewage water

- PV-plants

- Sensors- & monitoring equipment

- Battery storage

Concept

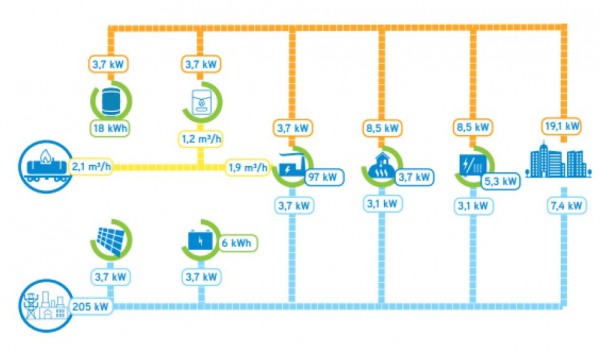

The figure below shows a simplified schematic representation of the project:

Energy solutions

The aim of the project was the implementation of an innovative hybrid grid to connect the different sectors of electricity, heat and gas. For this purpose, several technical facilities, such as: heat pumps, CHP, heat storage tanks, battery storages, PV systems and a sewage water heat exchanger were built.

Technologies considered in the design

Biogas-CHP:

As part of IKB Smart District project, a new biogas CHP were installed within showroom to convert biogas (biogas use proven through certificates) into electricity and heat. The electric power is 262 kW and the thermal power 375 kW.

Heat pumps:

Heat pumps are considered a key technology to integrate the heating sector into the electricity-based energy system. These devices use electricity to circulate hot/cold liquids, using the heat from outside air, geothermal heat, ground or sewage water. As part of IKB Smart District project, two heat pumps with a thermal power of 95.7 kW for each were installed. As an energy source, the wastewater from the nearby sewer is used.

Heat storage tanks:

To store the generated heat, several heat storage tanks with a total capacity of 19 m³ were built. The large storage tank with 10 m³ is situated in the showroom of Langer Weg 32 and the storage cascade with 9 m³ (6 x 1.5 m³) were situated in the technical room of Rossaugasse 2.

Electric heating element:

The installed Power-to-heat system is operated according to the flow heater principle and has an electrical power of 200 kW. Due to the almost lossless conversion, the thermal performance of 200 kW is also obtained. All components of the power-to-heat system (continuous flow heater, heat exchangers, main pumps, control technology) are located in the showroom of the project.

Inline heat exchanger for sewage water:

The installed inline heat exchanger is a module sewer heat exchange system for subsequent installation in existing sewers. The modules are introduced into the sewer using the available shaft infrastructure and are securely mounted. The heat exchange surface is completely supplied by warm wastewater (between 8°C and 22°C). The heat exchanger itself is perfused with heating water. Energy is thus extracted from the warm wastewater.

PV systems:

In addition to the existing PV plants, several new PV plants with a total capacity of 188.16 kWp were built. The new plants were integrated into the overall system.

Battery storage:

To match electricity supply and demand a battery storage with a capacity of 27.60 kWh has been installed in the showroom. As technology, a lithium-iron-phosphate battery was used.

Performance targets

expected amount of produced heat: 1,855 MWh/a

expected amount of produced electricity: 1,020 MWh/a

expected amount of reduced CO2: 863 t/a

Financing model

Direct investment of IKB 85%, national grant: 10 % and EC grant: 5%

Contracting authority: IKB Innsbrucker Kommunalbetriebe AG

Project manager: Sophia Neuner (IKB)

Manufacturer / supplier: Ortner (pipeline construction and main components); Doma (measuring and control technology); Uhrig (sewage water heat exchanger)

Cost breakdown

The total investment costs are in order of 3.2 Mio. €, Estimated payback time is: 10a

Implementation planning

1 - Design: 05/2017

2 – Public procurement: 01/2018

3 – Completion: 04/2019

Work progress

Milestones

Figure 1: CHP plant in the IKB Smart District fired with biogas

Figure 2: One of two heatpumps in the IKB Smart District

Figure 3: Heat storage tank cascade – 6 x 1,500 litres

Figure 4: Power-to-heat system in the IKB-Smart-District

Figure 5: Inline heat exchanger for sewage water

Figure 6: PV plant Showroom - Langer Weg 32

Figure 7: PV plant -Recycling Center - Rossaugasse 4

Figure 8: PV plant - Trientlgasse

Figure 9: Battery storage – Langer Weg 32

Monitoring System

The entire system has a modern process control system, which connects all components with each other. All measured values required for operation are recorded in the system. In order to assess the performance of the individual components, KPIs are calculated.

Monitored variables and figures

The following data is recorded for the Sinfonia project:

- energy input and output [kWhel, kWhth]

- reduction of CO2 [t/a]

Heat pumps: 20 yrs

Biogas CHP: 20 yrs

Measuring and control system: 15 yrs

Sewage water heat exchanger: 20 yrs

PV plants: 20 yrs

Buildings: 50 yrs

Pipe systems: 20 yrs

Battery storage: 8 yrs

Heat storage tanks: 20 yrs

Building owner

IKB Innsbrucker Kommunalbetriebe AG

Manufacturer/Supplier

Ortner (pipeline construction and main components)

Doma (measuring and control technology)

Uhrig (sewage water heat exchanger)

Contact

Sophia Neuner (IKB)

Project Manager