Power-to-heat

Name and address

Public swimming pool Amras

Amraser Straße 3

6020 Innsbruck

Austria

Map

Type of installation

In general the term Power-to-Heat is used to specifically describe the usage of electrical energy which is in excess from time to time. Energy excess occurs when the power input into the grid is exceptionally high or when the consumption of electricity is extremely low. These fluctuations known as volatility must be intercepted in order to stabilise the grid. The power must be transferred to storage points to ensure utilization at a later point in time. In the present project, surplus electricity is converted into thermal energy and subsequently stored. The stored energy is used at a later time for the operation (space heating, water heating, heat supply for ventilation systems) of the indoor swimming pool. As a result, less natural gas is used via the existing heating system.

Ownership

Innsbrucker Kommunalbetriebe AG

Capacity

Electric heating element

1 MWel

Heat storage tank

80m³

Detailed characteristics of the device / infrastructure / service

The project “Power-to-Heat” includes the following major components:

- power-to-heat unit,

- heat storage tank

Concept

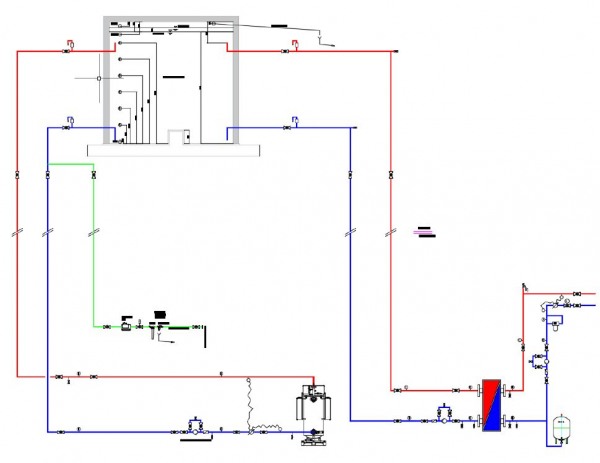

The figure below shows a simplified schematic representation of the project:

Energy solutions

The aim of the project was to substitute the use of natural gas for heat production. The power-to-heat system with the heat storage tank partially covers the energy requirements of the indoor pool and serves to stabilize the local power grid. The output of the system is 1.0 MW electrical, which, also corresponds to a thermal output of nearly 1.0 MW. In addition to the swimming pool, an 80.0 m³ non-pressurized heat storage tank is installed within the building. The water content is heated to 98 ° C by means of a power-to-heat system using the instantaneous water heater principle. This hot water is fed into the existing heating distributor.

Technologies considered in the design

Electric heating element:

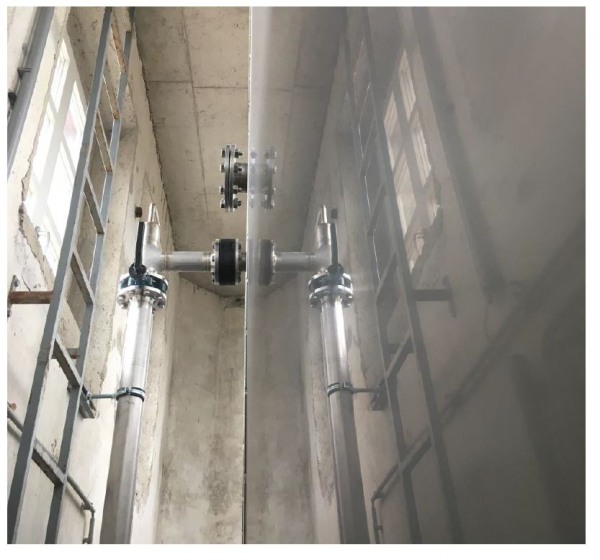

The installed Power-to-heat system is operated according to the flow heater principle and has an electrical power of 1 MW. Due to the almost lossless conversion, the thermal performance of 1MW is also obtained. All components of the power-to-heat system (continuous flow heater, heat exchangers, main pumps, control technology) are located in the technical room of the basement.

Heat storage tank:

To store the generated heat, a non-pressurized heat storage tank with a capacity of 80 m³ was built. The heat storage tank is located in the tower of the building. The tank could not be constructed like other tanks in advance. Due to the special situation, the tank had to be welded on site within the tower. The water is heated up to 98 °C by the power-toheat system.

Performance targets

expected amount of produced heat: 980 MWh/a

expected amount of reduced CO2: 168 t/a

Financing model

Direct investment of IKB 85%, national grant: 10 % and EC grant: 5%

Contracting authority IKB Innsbrucker Kommunalbetriebe AG: Project manager Sophia Neuner (IKB)

Manufacturer / supplier: Kapferer Installationen (pipeline construction, power-to-heat unit); Tankbau Freudenberger (heat storage tank)

Cost breakdown

The total investment are in order of 640,000 €, Estimated payback time is: 16a

Implementation planning

1 - Design 01/2018

2 – Public procurement 12/2018

3 – Completion 04/2019

Work progress

Milestones

Figure 1: Heat storage with 80m3 in the public swimming pool

Figure 2: Power to Heat with capacity of 1 MW from pupblic swimming pool

Figure 3: Transformerstation for the power to heat in the public swimming pool in Amras

Figure 4: Tower with heat storage in the public swimming pool

Monitoring System

The entire system has a modern process control system, which connects all components with each other. All measured values required for operation are recorded in the system. In order to assess the performance of the individual components, KPIs are calculated.

Monitored variables and figures

The following data is recorded for the Sinfonia project:

- energy input and output

- reduction of CO2 [t/a]

Power-to-heat unit: 20 yrs

Heat storage tank: 20 yrs

Pipe systems: 20 yrs

Building owner

IKB Innsbrucker Kommunalbetriebe AG

Manufacturer/Supplier

Kapferer Installationen (pipeline construction, power-to-heat unit)

Tankbau Freudenberger (heat storage tank)

Contact

Sophia Neuner (IKB)

Project Manager