Reichenauerstraße 94

Name and Address

Name of the demo site: NHT IN43

Address of the demo site: Reichenauerstraße 94 a,b,c,d / IN 43, 6020 Innsbruck, Austria

Map

City map highlighting the surface occupied by the demo site (source: http://city-map.innsbruck.gv.at)

Description

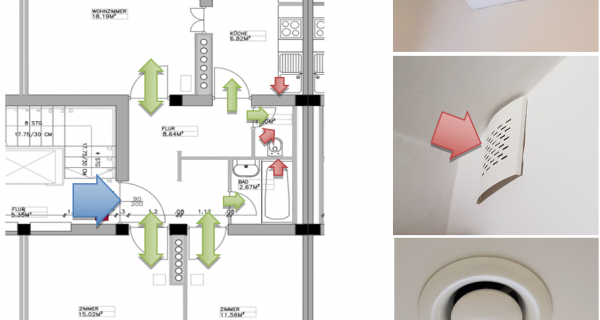

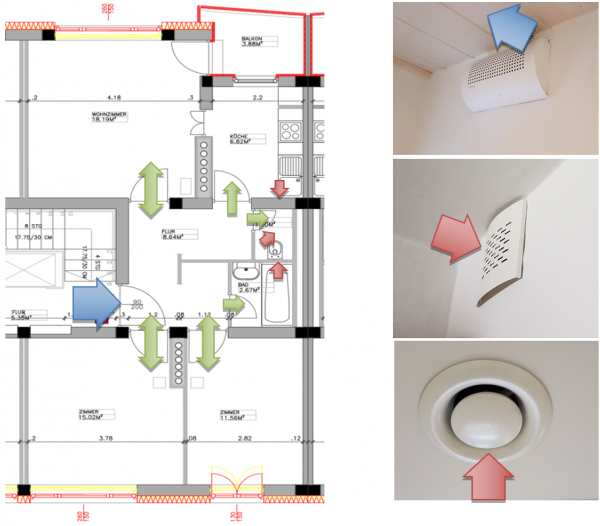

NHT already finished the innovative overall building renovation, consisting of the thermal renovation of walls (incl. loggias), ceiling, roof and windows with triple-glazing. The central ventilation system is also equipped with supply risers which distribute the air to the apartments.

The fresh air is only provided to the hallway. The extended cascade-ventilation principle was monitored and measured in a fully equipped prototype-flat by UIBK. Results were positive for low CO2, VOC and humidity concentration.

Ownership: Neue Heimat Tirol (NHT)

Gross conditioned floor area (EPC): 5.484 m²

Treated floor area (PHPP): 3,893 m²

Number of dwellings: 60

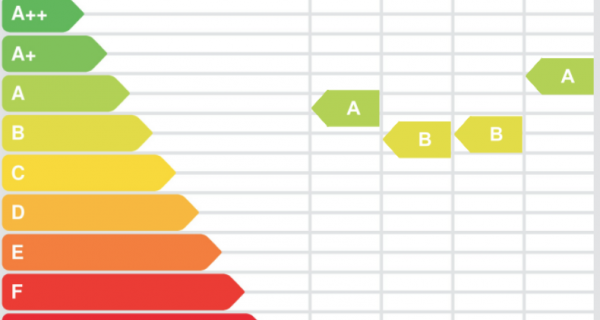

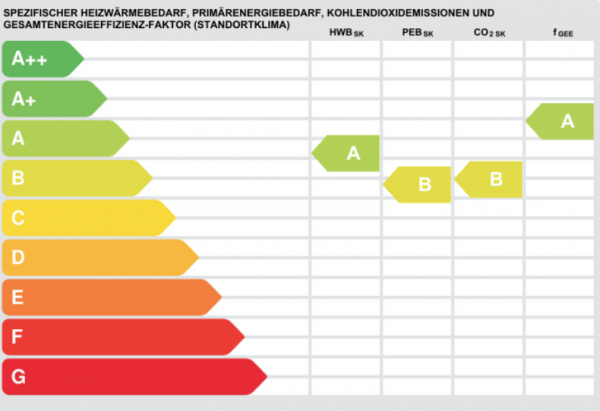

Heating demand (EPC)

BEFORE RENOVATION: 63,82 kWh/m²*a

AFTER RENOVATION: 23,8 kWh/m²*a

Heating demand (PHPP)

BEFORE RENOVATION: 167 kWh/m²*a

AFTER RENOVATION: 25 kWh/m²*a

Overall savings after completion of ventilation & heating system: 84%

All objects are patched via 1 long complex of buildings. (source: google)

Building envelope

IN43 stock is a building block constructed in the second half of the 20th century with related challenges in regards to insulation, electric cables, low-performing windows, uninsulated roofs and cellars, etc.

Technical system: Decentralised heating system

Energy performance certificate: Category C

Concept

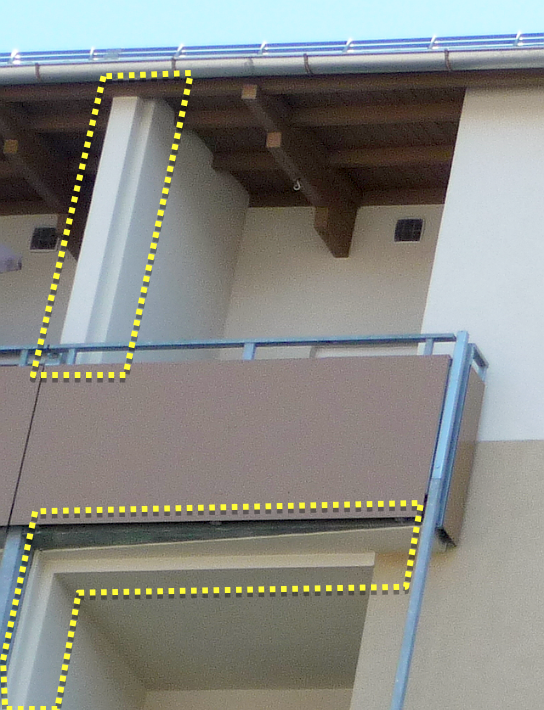

Thermal renovation of the walls, the ceiling, the roof and the windows with triple-glazing. The principle of “thermal bridge minimized design” was used to minimise the thermal bridges of the balconies.

Energy solutions

- The attics are insulated with a 32cm layer of highly effective glass wool

- The facade is additionally insulated with 18 cm of EPS

- The ceiling to the unheated basement is equipped with an additional 10cm layer of mineral wool

- Walls & ceilings to the stairway and basement are equipped with 16 cm of XPS

- DHW and space heating are equipped with efficient, modern bio-gas driven gas-fired boilers with a condensing technology

- There is LED lighting in all public spaces

- The PV-system was installed as a full feed system, so that the generated energy feeds the public grid while the Austrian agency for green electricity complements the missing energy

- The PV-system was installed as a full feed system, so that the generated energy feeds the public grid while the Austrian agency for green electricity complements the missing energy

Performances targets

The goal is to achieve a calculated energy consumption per m² of total used energy per conditioned floor area of about 28,8 kWh/m²*a (Space heating and DHW).

Financing model

The refurbishment is financed via a mix of reserves as well as local/ regional/ national/ EU funding and includes an increase of the monthly rent.

Envelope details

Roof to wall insertion section (thermal bridge)

- Insulation of the attic floor, U-value= 0.11 W/(m²K)

Ground to wall section (thermal bridge)

- Additional thermal insulation of the lowest storey ceiling, U-value= 0.29 W/(m²K)

Wall to fenestration section (thermal bridge)

- Main exterior wall: additional 18cm EPS insulation to the already existing 6cm cork insulation, U-value= 0.13 W/(m²K)

- Exterior wall to loggias: due to space restriction, additional 8cm highly effective PUR (λ= 0,026[W/(mK)) insulation, U-value= 0.27 W/(m²K)

- Replacement of windows to achieve a thermal performance that is 70 % better

Technical system

Mechanical ventilation

The distribution of air from the central ventilation system to the apartments is achieved via supply risers. The fresh air is only provided to the hallway. The extended cascade-ventilation principle was monitored and measured in a fully equipped prototype-flat prior by UIBK. Results were positive for low CO2, VOC and humidity concentration. 24 of the 60 apartments are already equipped with this ventilation system.

Electric renewable integration

Based on a roofing contract with IKB the PV system has been integrated into the building:

Nominal power of PV IN 43: 21 kWp; 140 m²

Mounting type: Roof mounted parallel

Elevation: 574 m a.s.l.

Tilt: 25°

Azimuth angle: 243°

Financial model: full feed system with feed-in-tariff

Stakeholders involved

Contracting authority: NEUE HEIMAT TIROL Gemeinnützige WohnungsGmbH

Project manager: Gerda Maria Embacher

Architect/Envelope Designer: Arch. DI Gerald Gaigg, Innsbruck

Technical system designer: Alpsolar Klimadesign OG, Innsbruck, Ing. Obwieser GmbH, Absam

Construction company: KPS Ötztalputz GmbH, Ötztal Bahnhof

Windows supplier: Akutherm Bauelemente GmbH, Innsbruck

Safety supervisor: Arch. DI Karin Kopecky, Rum

Carpenter: Huter & Söhne GmbH, Innsbruck

Energy consultant, scientific support: University of Innsbruck and Passive House Institute – Department Innsbruck

Refurbishment costs

Total investment of € 2,6 Mio.

Work Progress

The challenges during the refurbishment of residential buildings are complex and multi-layered. Financial and social aspects and challenges need to be considered, because the tenant has to co-finance some parts of the renovation, which requires the implementation of persuasion and tenant engagement activities. Furthermore, legal challenges also have to be solved. The most intensive persuasion is to be done in the field of nearly zero energy house renovation and especially in cases where tenants are living in the flats during the time of ventilation system installations and other intrusive renovation activities.

Within SINFONIA, NHT has pushed the installation of controlled ventilation with heat recovery as extended cascade-ventilation principle in IN43. For the time being 40% of the building users have agreed to implement this measure. Further extension is expected according to the fluctuations of the building users and corresponding rental contracts with new tenants.

Architectonic concept

Renewable energy sources

Prognosis of the yearly yield: 21,806 kWh/a

End-Energy use (EPC): Calculated with 68,9 kWh/m²*a

Energy efficiency certificate (EPC)

EnerPHit pre-certificate for stepwise refurbishment (PHI)

EnerPHiT certification is foreseen shortly

Building owner

Neur Heimat Tirol (NHT)

Architecture / Engineering

Arch. DI Gerald Gaigg, Innsbruck

Contact

Standortagentur Tirol

Tel : +43.512.576262