Transformer Station UW Mitte

Name and Address

Administration building IKB, Salurner Straße 11, 6020 Innsbruck, Austria

Map

Type of installation

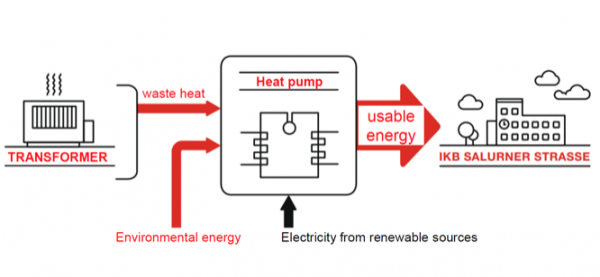

Within the project "heat recovery transformer station UW Mitte", the waste heat from a transformer of the substation UW Mitte is used together with the energetic potential of the environment as the primary source for a heat pump process. For peak load coverage, a gas boiler system was installed as a backup. It is expected that an average of 75 percent of the annual heat demand will be covered by the installed heat pump system.

Ownership

Innsbrucker Kommunalbetriebe AG

Capacity

Heat pumps: 87,3 kWth

Natural gas hot water boiler: 96 - 300 kWth

Heat storage tanks: 4,000 litres

Detailed characteristics of the project

The project “Heat recovery transformer station UW Mitte” includes the following major components:

- heat pumps,

- natural gas hot water boiler,

- heat storage tanks

The figure shows a simplified schematic representation of the project:

Energy solutions

The energy supply of an administration building by an air-water heat pump system is a common solution on the market. The project receives innovative content from the additional use of waste heat from the transformer substation, which was previously unused. This leads to an increase in the efficiency of the heat pump. In addition, there is another positive effect. The use of the heat pump results in an active cooling of the transformer substation, whereby a longer life is expected.

Technologies considered in the design

Heat pumps

The renewable heat is generated by two air-water heat pumps (with 34.9 kW and 52.4 kW) with five outdoor units, which are situated on the ceiling above the transformer substation. The regulation of the heat pumps is weather-related with a sliding operating mode.

Natural gas hot water boilers

Two new hot water boilers (with 48-150 kW) were installed to cover the peak load.

Heat storage tanks

To store the generated heat, two heat storage tanks with a capacity of 2,000 litres each were implemented. This results in the possibility of compensating an irregular operation of the transformer substation.

Performance targets

- expected amount of produced heat (heat pumps): 300 MWh/a

- expected amount of produced heat (gas boiler): 200 MWh/a

- expected amount of reduced CO2: 71 t/a

Financing model

Direct investment of IKB: 85%, national grant: 10 % and EC grant: 5%

Stakeholders involved

Contracting authority: IKB Innsbrucker Kommunalbetriebe AG

Project manager: Sophia Neuner (IKB)Contracting authority: IKB Innsbrucker Kommunalbetriebe AG

Manufacturer/Supplier: E. Rainalter GmbH

Costs

The total investment costs are in order of 0.21 Mio. €, Estimated payback time is 10yrs

Work Progress

Figure: outdoor units of the air-water heat pumps

Figure: indoor unit of the air-water heat pumps

Figure: two heat storage tanks with 4,000 litres capacity

Figure: natural gas hot water boiler for peak load coverage

Monitoring system

The entire system has a modern process control system, which connects all components with each other. All measured values required for operation are recorded in the system. In order to assess the performance of the individual components, KPIs are calculated.

Monitored values and figures

The following data is recorded for the Sinfonia project:

- energy input and output [kWhel, kWhth]

- reduction of CO2 [t/a]

Estimated lifetime

Heat pumps: 20 yrs

Hot water boiler: 20 yrs

Heat storage tanks: 20 yrs

Pipe systems: 20 yrs

Building owner

IKB Innsbrucker Kommunalbetriebe AG

Manufacturer/Supplier

E. Rainalter GmbH

Contact

Sophia Neuner (IKB)

Project Manager